SLZ2000

- The SANY SLZ2000 is an advanced asphalt mixing plant designed to deliver high-quality asphalt with enhanced productivity. Featuring cutting-edge technology such as extra-long drying drums and boiling-type mixing, it ensures consistent, efficient production for large-scale road construction projects.

Capacity:

160-180 TPH

Total Power:

783 kW

Drying Drum:

Φ2×9 m

Fuel:

Light oil, heavy oil, natural gas, liquefied gas

Burner:

14 MW

Hot Elevator:

18.5 kW

Screening Motor:

2×2.9 kW

Capacity of Mixer:

3.5 t

Mixer Motor:

2×45 kW

RAP Rated Capacity:

180 TPH

About SLZ2000

The SANY SLZ2000 is engineered for high-capacity, efficient asphalt production with 160-180 t/h rated capacity. It combines extra-long drying drum technology for improved heat exchange efficiency and intelligent production systems for automated operation and monitoring. The plant is equipped with advanced weighing and mixing technologies, ensuring accurate material control and reduced operational costs. Its robust design and user-friendly interface make it the ideal choice for large-scale construction and roadwork, delivering exceptional reliability and performance.

FEATURES

1. Efficient Asphalt Production

1. Efficient Asphalt Production

- Extra-long RAP drying drum with optimal “three-zone blade” design for better heat exchange and efficiency.

- RAP material temperature reaches up to 140°C, ensuring uniform heating and high-quality asphalt.

- Higher efficiency in heating, resulting in 15% improved heat exchange.

2. Boiling-Type Mixing Technology

2. Boiling-Type Mixing Technology

- Spirally arranged mixing blades ensure high uniformity and superior efficiency in asphalt mixing.

- Axial major cycle and tangential minor cycle increase mixing efficiency by 20%.

- Increased mixing speed, with a decreased discharge time by 3 seconds, ensuring faster production cycles.

3. Intelligent Production Technology

3. Intelligent Production Technology

- 1-button startup and shutdown, with auto temperature control for enhanced ease of operation.

- Auto calibration and equipment health management through intelligent monitoring systems.

- Real-time monitoring and adjustments ensure optimal performance across all production phases.

4. Accurate Weighing Technology

4. Accurate Weighing Technology

- Large and small gate discharging technology ensures accurate measurement of aggregates with an error margin of less than 20 kg.

- Asphalt/aggregate ratio bias controlled to less than 0.1%, ensuring high consistency in mix production.

- Advanced weighing system using frequency conversion to reduce errors to just 1 kg.

5. Enhanced Safety and Efficiency

5. Enhanced Safety and Efficiency

- Material flow detection and high-temperature warning systems ensure safe operation.

- Flameout protection and auto shutdown in case of safety concerns, ensuring consistent safety standards.

- Optimized design for easy maintenance, reducing downtime and improving operational efficiency.

RELATED PRODUCTS

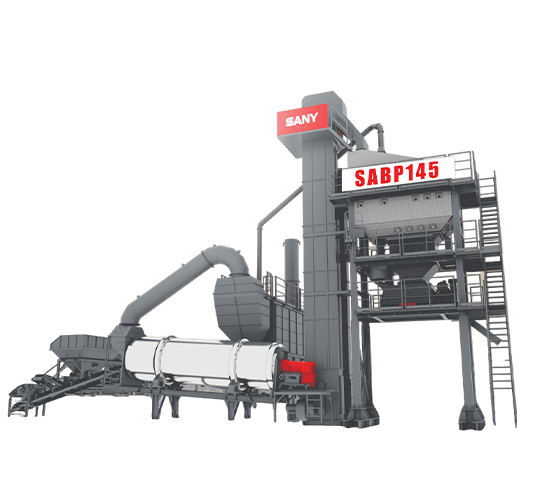

SABP145

SABP145

- Capacity: 145 TPH

- Preparation Time Reduced by: 15%

- Fuel Efficiency Increased by: 10%

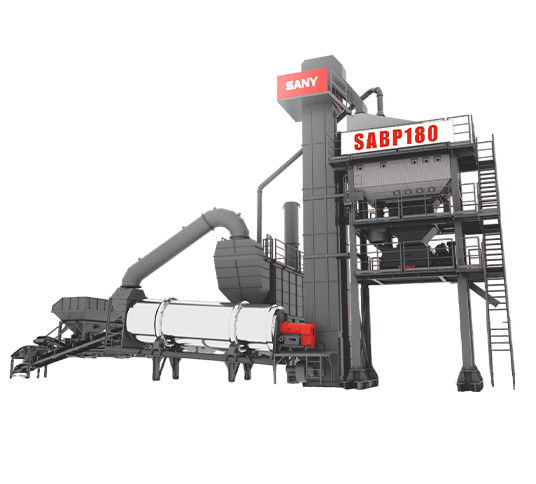

SABP180

SABP180

- Capacity: 160-180 TPH

- Preparation Time Reduced by: 1hr

- Fuel Efficiency Increased by: 10%