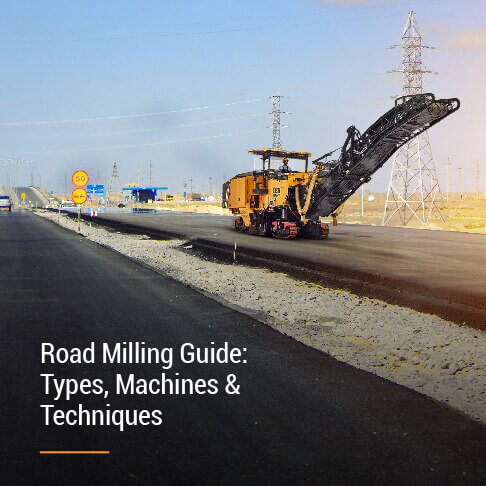

The Ultimate Guide to Milling in Road Construction

Category: Milling Machine, Road Machinery | 28 May 2024

Road construction is a complex process that requires precision at every step to ensure the durability and safety of the finished roadways. One of the critical steps is milling, a technique used to remove the top layer of existing pavement. This task is performed by specialized milling machines, designed to prepare the surface for new asphalt effectively. In this blog, we cover everything you need to know about milling in road construction, from the benefits and processes to choosing the right road milling machine for your project.

What is Milling in Road Construction?

Milling, commonly known as cold planing, is a fundamental process in road construction that involves the removal of the top layers of existing asphalt. This method is crucial for paving the way for new material, ensuring that the addition of new layers does not increase the pavement's overall height. By stripping away worn, damaged, or deteriorated asphalt, milling provides a smooth, even surface essential for the new asphalt to adhere properly. This technique not only prepares the roadbed for resurfacing but also helps maintain the original engineering integrity of the roadway.

Advantages of Milling in Road Construction

Milling in road construction brings a multitude of advantages, making it a preferred method for maintaining and upgrading roadways. Here are the key benefits outlined in more detail:

- Road Maintenance: Regular milling helps remove cracks, ruts, and other surface defects that can lead to larger structural issues if left unaddressed. It is an integral part of preventative maintenance that keeps roadways safe and functional.

- Correcting Surface Irregularities: Milling allows for the correction of uneven surfaces and imperfections. This levelling effect is crucial for the longevity and drivability of the road, ensuring a smooth ride for vehicles.

- Improving Skid Resistance: By removing the smooth, polished top layer of asphalt that can make roads slippery, especially in wet conditions, milling helps to increase the roughness of the road surface, thereby enhancing skid resistance.

- Extending Roadway Life: By allowing for the placement of new asphalt over a sound base, milling extends the overall life of the roadway. This refreshed surface can better withstand the rigors of daily traffic and environmental conditions.

- Cost Efficiency: Milling is cost-effective as it allows the recycled materials to be reused in the new asphalt mix, reducing the need for new materials and minimizing waste.

- Recycling of Old Materials: Milling promotes environmental sustainability by recycling the removed asphalt, which can then be reused in creating new asphalt mixes. This practice not only conserves natural resources but also reduces the environmental impact associated with the extraction and processing of new raw materials.

- Time Efficiency: Milling is a swift process that can strip large areas of asphalt within a short period, thereby speeding up the road rehabilitation process. This efficiency leads to quicker project completions and less disruption for traffic, benefiting both road users and construction teams.

How is Milling Done?

The milling process involves large road milling machines equipped with a rotating drum that removes and grinds the pavement. These machines are capable of milling to various depths and widths, depending on the project requirements. Operators must adjust the speed and drum rotation to ensure even surface removal and optimal machine performance.

Key Factors to Look for When Buying a Road Milling Machine

- Width and Depth of Milling: Choose a machine that matches the required width and depth specifications of your project.

- Advanced Controls: Select machines with precise controls for depth, speed, and slope for accurate milling operations.

- Durability: Opt for robust and well-built machines that can endure the rigorous demands of road construction.

- Ease of Operation: Ensure the machine features user-friendly controls and ergonomic design to enhance operator comfort and productivity.

- Maintenance Requirements: Look for machines with straightforward maintenance protocols and accessible parts to minimize downtime.

- Efficiency: Consider the fuel efficiency and environmental footprint of the machine to reduce operating costs and environmental impact.

- Versatility: Choose a versatile milling machine capable of accommodating various attachments for different milling tasks.

Road Milling Machines by SANY India

At SANY India, we are a globally recognized leader in the construction machinery industry, renowned for our innovation and reliability. Among our extensive product range, our milling machines are particularly noted for their exceptional performance and durability in road construction projects. We proudly offer several models, each meticulously designed to meet the specific challenges and demands of modern roadwork.

- SCM1000C-8: Known for its powerful performance, the SCM1000C-8 is ideal for precise asphalt pavement milling. It features a large drum equipped with durable tungsten carbide teeth, ensuring a clean, uniform surface finish.

- SCM1300C-8: Designed for heavy-duty road projects, the SCM1300C-8 offers robust construction and high efficiency. Its large rotating drum and sharp cutting teeth tackle challenging tasks effortlessly.

- SCM2000-8S: The SCM2000-8S stands out in every road project with its exceptional power and performance. It efficiently mills asphalt with precision, supported by a potent engine and a well-designed drum.

To Sum Up

Choosing the right milling machine significantly impacts the success of your road construction projects. By understanding the milling process and the features of high-quality equipment, you can ensure efficient, precise, and cost-effective road milling machines. Consider the SCM1000C-8, SCM1300C-8, and SCM2000-8S models for their proven capabilities and enhance your project outcomes today.